Lab maintenance is crucial to get correct results as well as to increase the service life of expensive equipment. Yet, it is a costly affair if not well handled in that it requires so much when it comes to maintenance. The following are some of the ways that can be used to cut on expenditure while at the same time ensuring that the laboratory is well equipped with the best equipment.

Implement a Regular Maintenance Schedule

Concisely, the coupled strategies of having a preventative maintenance plan and keeping a close check on maintenance costs make it possible to manage the expenses of maintaining laboratory equipment. Periodic examinations or regular check-ups will enable this to be done thus preventing cases where extensive repairs have to be done.

Benefits of Regular Maintenance

- Preventative Care: This is important as most of the time, it will make you avoid the shock that comes with a breakdown that you have not planned for.

- Prolonged Equipment Life: Regular maintenance keeps your equipment in good condition and there is a reduced chance that you will have to replace the equipment soon.

- Improved Performance: Equipment that is well maintained reduces the rate of inaccuracies therefore increasing the reliability of results.

Train Staff Properly

It is for this reason that staff in laboratories should be well-trained in the maintenance of all equipment. For all the users, the proper usage and fundamental care of all the equipment should be explained to them well. This eliminates cases of user errors that may in one way or the other cause damage to the equipment and require repairs.

Key Training Areas

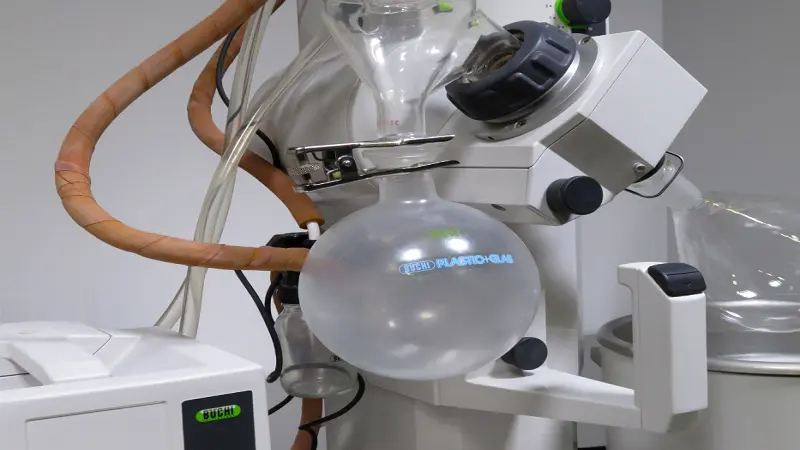

- Correct Usage: Enlightening the staff using the equipment, for instance, a 50L rotovap, reducing improper use of the aid is achieved which results in increased durability.

- Basic Troubleshooting: Teaching basic troubleshooting helps most problems to be solved by staff and greatly cuts down on professional intervention.

- Cleaning and Calibration: Hence, the cleaning and calibration processes should be conducted as often as possible to improve accuracy and efficiency. Make sure that the staff of the clinics recognize these procedures.

Source Quality Parts and Consumables

This will keep breakdowns at a minimum and your equipment running effectively since the parts and consumables are of good quality and acquired from reliable sources. This implies that while the cheaper alternatives of the equipment may have lower costs in the first instance, the equipment will require frequent replacements and repairs.

Choosing the Right Suppliers

- OEM Parts: In most cases, go for OEM (Original Equipment Manufacturer) parts as they are made to fit your equipment; thus, are more compatible.

- Reliable Suppliers: Cooperated with stable suppliers and OEM rotovap chiller factories to purchase relatively high-quality spare parts and accessories.

- Bulk Purchasing: Personal ordered consumables could be bought in larger quantities for they will attract discounts and the stocks will be replenished frequently.

Utilize Warranty and Service Contracts

Most laboratory equipment have service contracts or warranties that allow for servicing and repair of the item within a given period. Using these can greatly reduce the cost of repair and replacement.

Maximizing Warranties and Contracts

- Understand Coverage: Make sure that whichever equipment you are using comes with a different warranty or service contract which can help you to avoid extra charges which should have been catered for by the warranty or service contract.

- Timely Servicing: Maintain the manufacturer’s recommended servicing schedule as this adheres to the warranty conditions of the car.

- Negotiating Contracts: While buying new equipment, sometimes a company makes agreements for services which may entail that new equipment shall have a regular check-up and in some cases servicing done if they break down.

Implement a Monitoring System

Thus, it is crucial to install control over your laboratory equipment that can help monitor its work and reveal the presence of problems. Numerous contemporary laboratory equipment are equipped with monitoring functions that can be used to obtain information concerning the equipment’s condition in real-time.

Benefits of Monitoring Systems

- Early Detection: Failure detectors can inform you about issues when they are still manageable and before they magnify.

- Data-Driven Decisions: By using the data obtained from the monitoring systems one is in a position to determine the right time to fix or replace some of the equipment.

- Increased Efficiency: Supervisory systems assist in checking that equipment is running optimally and thus not straining on energy and wearing and tearing out.

Invest in Energy-Efficient Equipment

Efficient laboratory equipment can go a long way in terms of costs in the long run. These instruments are built to consume less energy and therefore, the energy costs of an enterprise are lowered and the life of the instruments is prolonged since they are not strained by high power usage, hence, the need to repair them frequently is minimized.

Choosing Energy-Efficient Options

- Energy Star Ratings: Select pieces with high Energy Star ratings, these are signs of high energy efficiency in the equipment.

- Modern Technologies: Purchase relatively older models that are incorporated with modern energy-saving technologies.

- Lifecycle Costs: Energy consumption should also be taken into consideration when deciding on the procurement of new equipment.

Schedule Regular Professional Servicing

Concerning some problems, routine inspections, and timely repairs help to avoid the majority of failures, but when it comes to complex equipment it is necessary to observe compliance with servicing schedules. Experts hold specialized knowledge to carry out proper and ideal inspections and repairs since they represent your equipment.

Benefits of Professional Servicing

- Thorough Inspections: Professional servicing also entails more profound tests that may not be done during general servicing.

- Expert Repairs: Nonetheless, professional people are in a position to work on a complex repair job with precision and therefore do not cause further deterioration to the house.

- Manufacturer Recommendations: In professional servicing, service keeps to the manufacturer’s guidelines to retain warranty and maximum efficiency.

Laboratory equipment management is another area that, when done right, can save a lot of cash while making sure that the equipment is delivering accurate results. The strategies of preserving cost in maintenance include, developing a regular check-up plan, staff orientation, acquiring parts, utilizing warranties, overseeing equipment, procuring an energy efficient model, professional servicing among others.

Following such recommendations, laboratories are able to minimize time during which equipment is out of service, increase its useful life as well as ensure minimal expenditure towards repair of the ailing tools. These methods can range from upgrading your small lab equipment such as 50L rotovap or you are a large firm directly sourcing from OEM rotovap chiller factories, then these practices will assist in keeping high the standards of your lab. It is therefore evident that spending quality time and actual money in making sure that all the equipment in the lab is well maintained is worth the effort as it increases efficiency and productivity of all the equipment.